Ahead of Formnext 2025, we sat down with Frédéric Larouche, CEO, AP&C (a Colibrium Additive Company) to discuss how customers’ requirements are shifting, sometimes rapidly, as they continue to industrialize and deploy larger format laser powder bed fusion (L-PBF) printers and larger fleets.

In this Q&A we cover how customers’ powder requirements are changing and what that means for the wider metal additive manufacturing industry. And, how AP&C is responding to growing customer needs for cost-effective options on fine particulate powders.

Q: When it comes to powders, which is the most important for our customers that are already in large scale production – is it quality, delivery or cost?

A: Quality has always been (and still is)the main factor for customers—regardless of the additive manufacturing maturity. They customers want to qualify and demonstrate the benefits of L-PBF technology, before advancing to larger-scale additive manufacturing.

However, when customers process to large scale additive production, delivery becomes increasingly important. Once manufacturing has started and scaled-up operations are in place, manufacturers need to have a reliable delivery so that they can supply their product to their customers on time.

Many of our customers have long since progressed beyond the validation stage or developing new processes and have shifted to large scale production. So, we’re now seeing that cost is becoming an equally important factor for our customers. This is something we are working with our SQDC – Safety, Quality, Delivery, Cost framework.

AP&C has a rigorous, continuous improvement mindset that aligns with our customers’ ethos, and that helps us remain focus and competitive in the ever-evolving metal powders market.

Q: Looking at L-PBF customers is there a significant shift on the type of powder particle size distribution (PSD) being used for production?

A: Indeed, it has evolved and especially this year we seen the most significant change we have seen over the last 10 years. The last time we had a change of this magnitude, on the powders side, was back in 2015 when L-PBF demand surpassed electron beam powder bed fusion (EB-PBF) demand. Prior to 2015, the EBM market was larger than laser—especially for titanium—but since then there has been a significant increase in demand from the laser side of the industry.

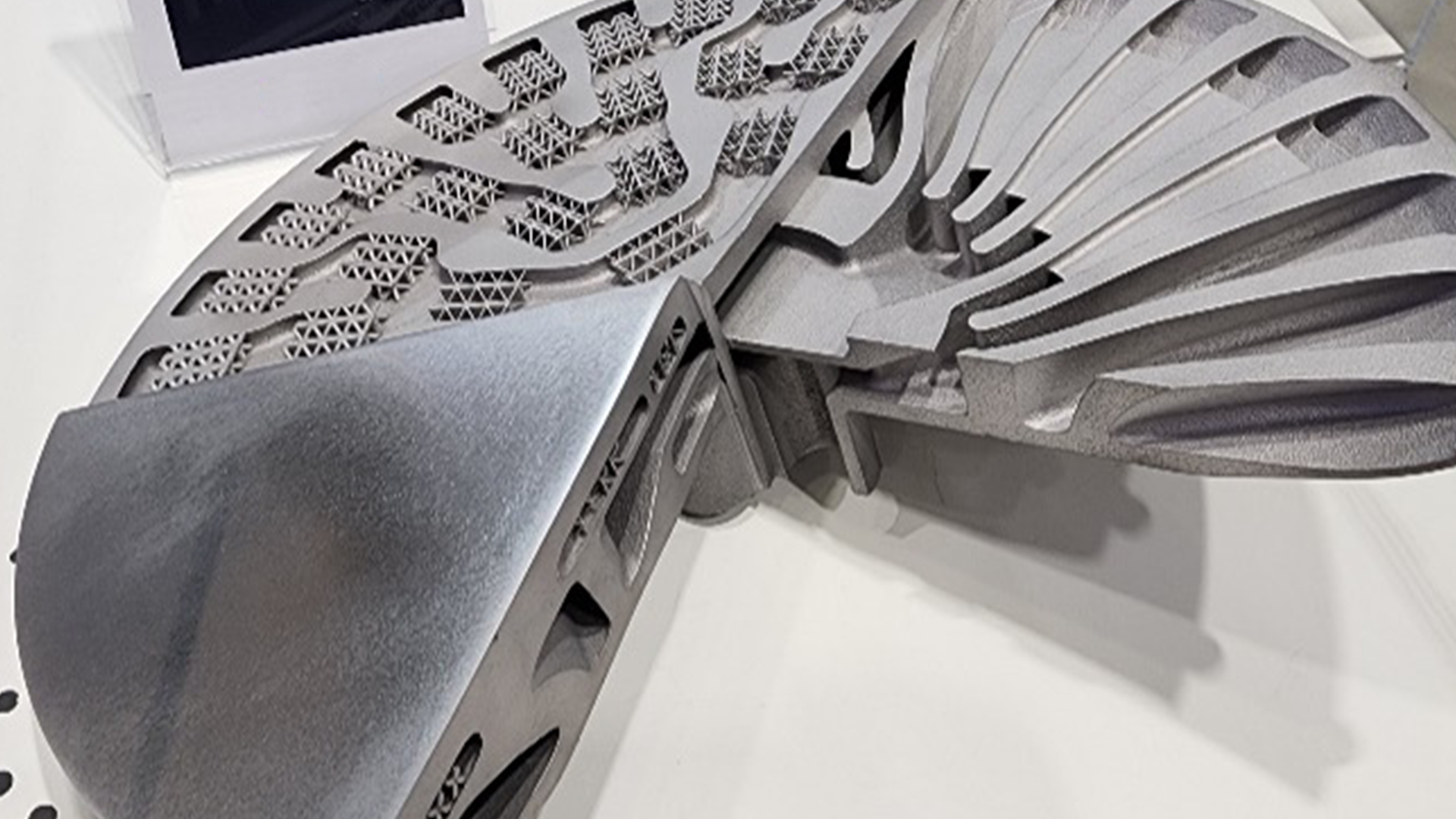

As the varying needs of L-PBF customers grow, many PSDs of powder can be used. We see that customers are not just looking for small size, high resolution, high accuracy, perfect parts anymore, they are moving to printing lower cost using thicker build layers. The printing process has evolved and improved so much over the years that the overall cost of printing is decreasing, so the powder becomes a more important fraction of the total printing cost.

Manufacturers are now moving to powders that are coarser or have a wider PSD to lower the cost of printing. However, this does come with a trade-off: often a higher surface roughness or lower resolution builds but with the benefit of a faster printing process. We used to see a lot of 15-45 µm powders being used for laser, but more recently it has moved to 15-53 µm, 20-63 µm, with some use cases being 15-90 µm or 15-106 µm. In some exceptional cases in less-regulated applications, we have seen completely coarse powders being used for L-PBF ―the same type used with EB-PBF.

Q: Why has there been such a step-change after 10 years?

A: We were waiting for it, because of the impact of AP&C’s customers investing in and deploying larger machines but were surprised at how fast the need emerged.

We have long been one of the promoters of using a wider PSD, because we see the added value and potential for reduced costs on larger scale printing. We have also performed in-house studies that show the feasibility of wider PSD powders. We believe the reason it has changed so quickly is that there are now more non-regulated applications using metal additive manufacturing, and those industries can often respond faster than regulated industries.

Q: How does AP&C support its customers’ industrialization strategies with handling large quantities of powder?

A: AP&C is best-known for suppling metal powders, but we are so much more than that. We have handled powder at industrial scale for many years, so we have had to develop efficient ways of handling and producing powder. We also have a lot of experience with Environment, Health, and Safety (EHS) with many sizes of powder.

We know that many, if not all, our customers feel the need to be more efficient and productive in the way that they use and handle powder. We often support our large-scale customers by supplying them with some of our equipment. We have customized equipment that has been extensively used and tested and has shown to be robust for large-scale production. For example, some of our sieving equipment can sieve 50 times faster than the equipment our customers were previously using. This is added value, alongside supplying powder and providing expert guidance, that we already provide to our customers.

Q: How does AP&C help drive down powder production costs?

A: Using the SQDC framework, and applying our continuous improvement mindset, we continue to improve and develop our technology. Today, we have 17 atomizers in production, just outside Montreal, in Canada, and are focused on making them as efficient and cost-effective, as possible. We are also running multiple programs to improve yield and post-processing productivity to lower the cost of transforming raw powder into the high-quality powder we ship to our customers every day.

Q: What are customers’ expectations, especially those in highly-regulated industries, around traceability?

A: It is fundamental and one of the top requirements that we have in all the industries we supply. Another large part of the work we undertook to be more efficient was integrating a robust digital infrastructure. We recently implemented a manufacturing execution system (MES) to control and manage everything. So, not only do we have complete traceability―knowing who touched the powder and when― we also have real-time access to the production parameters from the equipment. This is one big area of improvement, as we can leverage all the digital data with artificial intelligence (AI) to make our processes even more efficient.

Q: Where else are you harnessing AI within AP&C?

A: We are at the beginning of our AI journey. We have been working with a new system that can measure the yield of particles being produced in real time, which is one of the most important factors in our production costs.

With our previous system, we needed an experienced operator to look at the production yield manually, but we wouldn’t have the data generated by the manual adjustments until a day or two later. Now, with real-time feedback, we can tune the parameters and detect the PSD of the powder with high precision. Our 17 atomizers are all equipped with sensors, and we have the digital infrastructure and foundations to harness the potential of AI, but it is really the next step in the process.

Q: From a sustainability perspective, what can be done to recycle scrap or off-spec powder?

A: There is an importance to recycle in a circular economy. We have been developing solutions for scrap and off-spec powder that would typically be disposed of. For example, for titanium, we are alloying them.

We are exploring new technologies that can use off-spec or scrap powder as the starting material. We are working on a process that remove contaminants to produce fresh reworked powder that can be used again in a printer. Many customers want costs to be as low as possible, and this could be one way for manufacturers to use less expensive powder in their prints.

However, it is important to stress that while recycled powders can be used, the process of creating them must be done the right way, as there are a lot of risks involved―especially for companies in highly-regulated sectors where contamination needs to be avoided at all costs.

Q: Outside of additive manufacturing, how are you responding to the trend for using Titanium for large-scale metal injection molding (MIM)?

A: Using fine particles to do MIM has been something has been talked about forever. Over the years we have seen many projects come close to scale up only to fail.

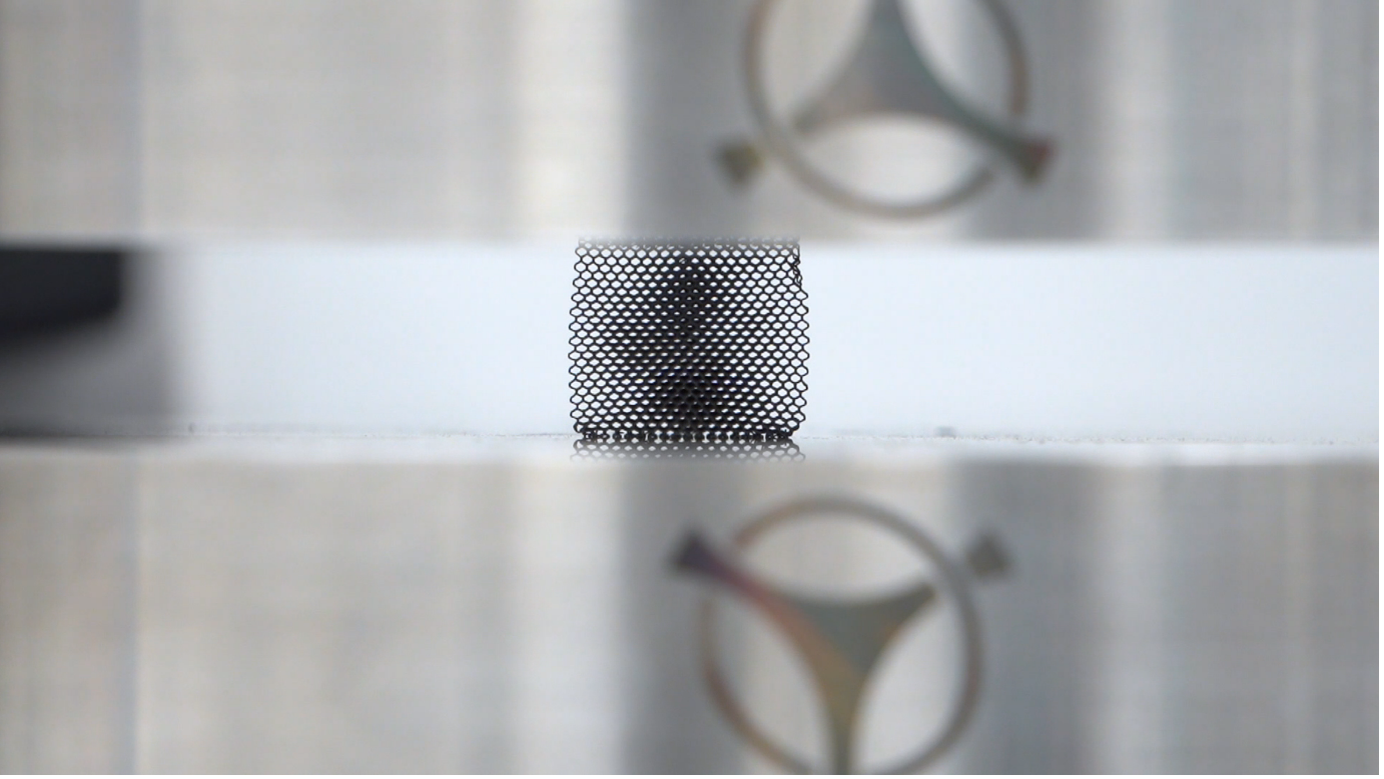

However, it seems to be now finally happening, as the technology matures. Titanium is a very reactive metal to work with but the feedstock being developed today has minimized the reactivity between the metal powder, allowing parts with good mechanical properties, microstructure, and surface finish to be produced. These feedstocks use a very fine 0-20 µm powder that is easy to sinter and can be sintered at lower temperatures. This has opened the ability to create titanium MIM parts with mechanical properties that were not achievable in the past.

MIM is now more mature than additive manufacturing for large scale production. It is now being used to create sports goods and consumer electronics and is scaling up at a rapid rate.

Summary

The metal powder market is evolving as additive manufacturing printers become larger and the volume of printing that companies undertake becomes greater.

With increasing volumes of additive manufacturing parts, the cost of the powder becomes a big part of the overall cost. While fine particle powder still provides the highest quality parts, many non-regulated industries don’t need this level of precision, opening the door to cheaper and wider PSD powders to be used. However, anyone using these powders needs to realize that there are some trade-offs that need to be made—which may not always be suitable for highly-regulated industries.

--

If you’d like to find out what kind of powder may be suitable for your application, considering part performance, scale of supply, and cost requirements, then the technical team at AP&C are available to discuss the available option for your specific needs.

Get in contact with AP&C team today to discuss your requirements or meet Frédéric and the team at Formnext in Hall 11.0, Booth D41 #Formnext2025 #AdditiveManufacturing