About Colibrium Additive

Partnership is the core of what we do

and who we are at Colibrium Additive

We offer a suite of products to help you unlock the full potential of additive manufacturing, and we have the world's largest team of additive experts who are uniquely suited to guide your additive journey. So, whatever you design and build, let's work together to show you a new way.

For the ready

Colibrium Additive – a GE Aerospace company – is a world leader in metal additive design and manufacturing, a pioneering process that has the power and potential to transform businesses. Through our integrated offering of additive experts, advanced machines, services and quality powders, we empower our customers to build innovative new products. Products that solve manufacturing challenges, improve business outcomes and help change the world for the better.

Electron Beam Powder Bed Fusion (EB-PBF) printers

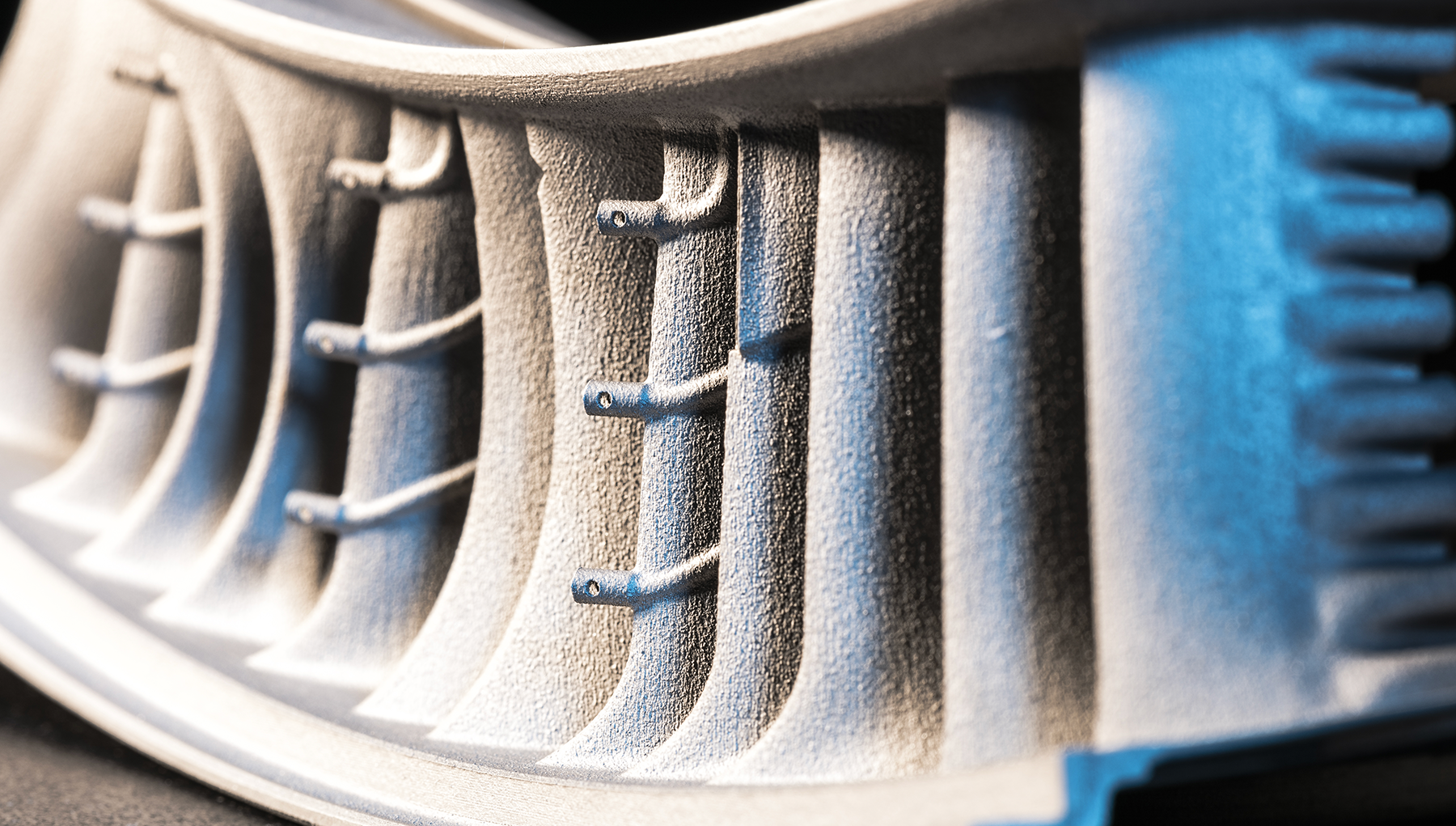

Colibrium Additive's EB-PBF printers are ideally suited for producing dimensionally accurate parts that need to be created quickly and efficiently. Working in a vacuum using a high-power electron beam for high melting capacity and productivity, the EB-PBF process delivers stress-free parts with better material properties than casting.

Laser Powder Bed Fusion

(L-PBF) printers

To create components with complex geometries requiring exceptional precision, Laser Powder Bed Fusion is the ideal approach. Our L-PBF machines use lasers to melt layers of fine metal powder and create complex geometries with incredible precision directly from a CAD file. Several different machine envelope sizes— including one of the largest powder-bed metal additive systems in the world — are available to meet the needs of any industry.

AP&C

A Colibrium Additive Company

AP&C has 10+ years of experience working with major biomedical and aerospace OEMs. AP&C supplies the highest-quality AM powder at competitive prices.

AP&C’s mission is to enable the production of high-quality parts made from titanium and other high-melting-point alloys in additive manufacturing and powder metallurgy processes.

AP&C’s mission is to enable the production of high-quality parts made from titanium and other high-melting-point alloys in additive manufacturing and powder metallurgy processes.