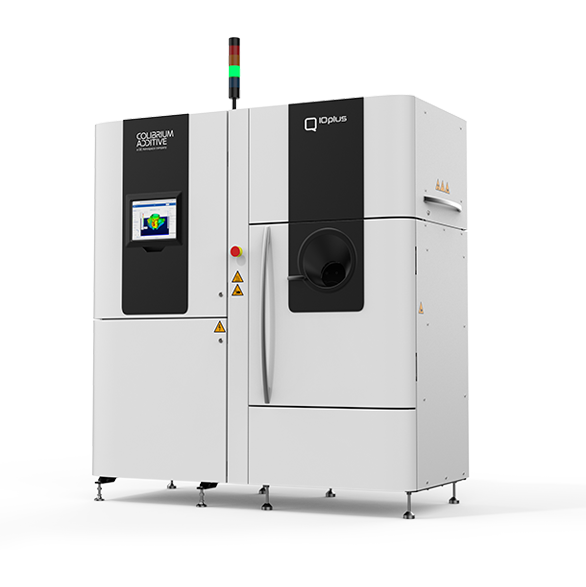

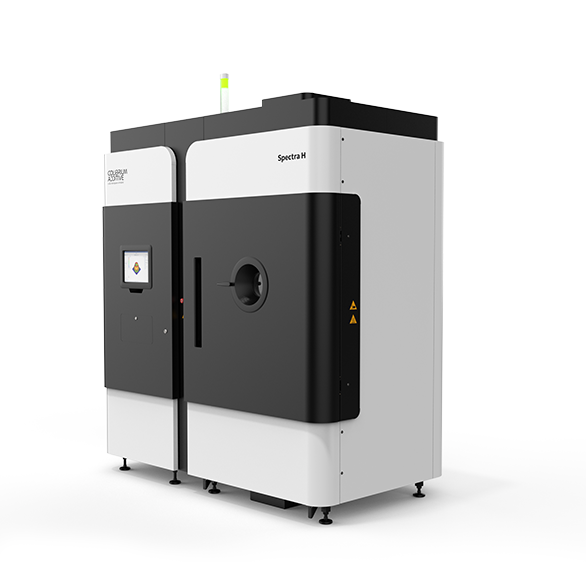

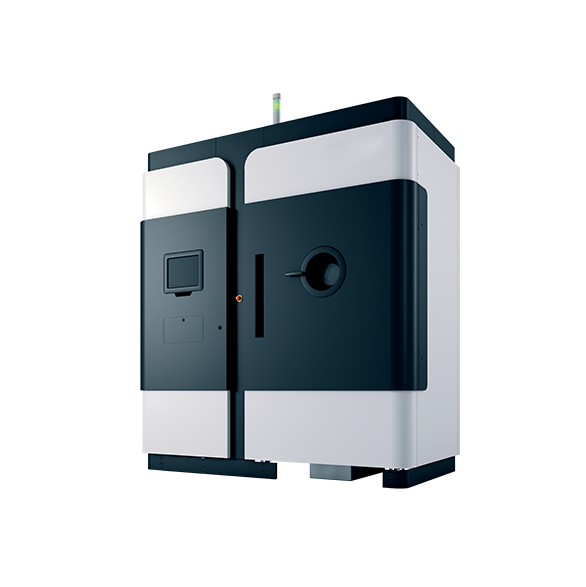

Spectra M

Revolutionizing Orthopedic Implant Manufacturing

The future

of medical additive manufacturing

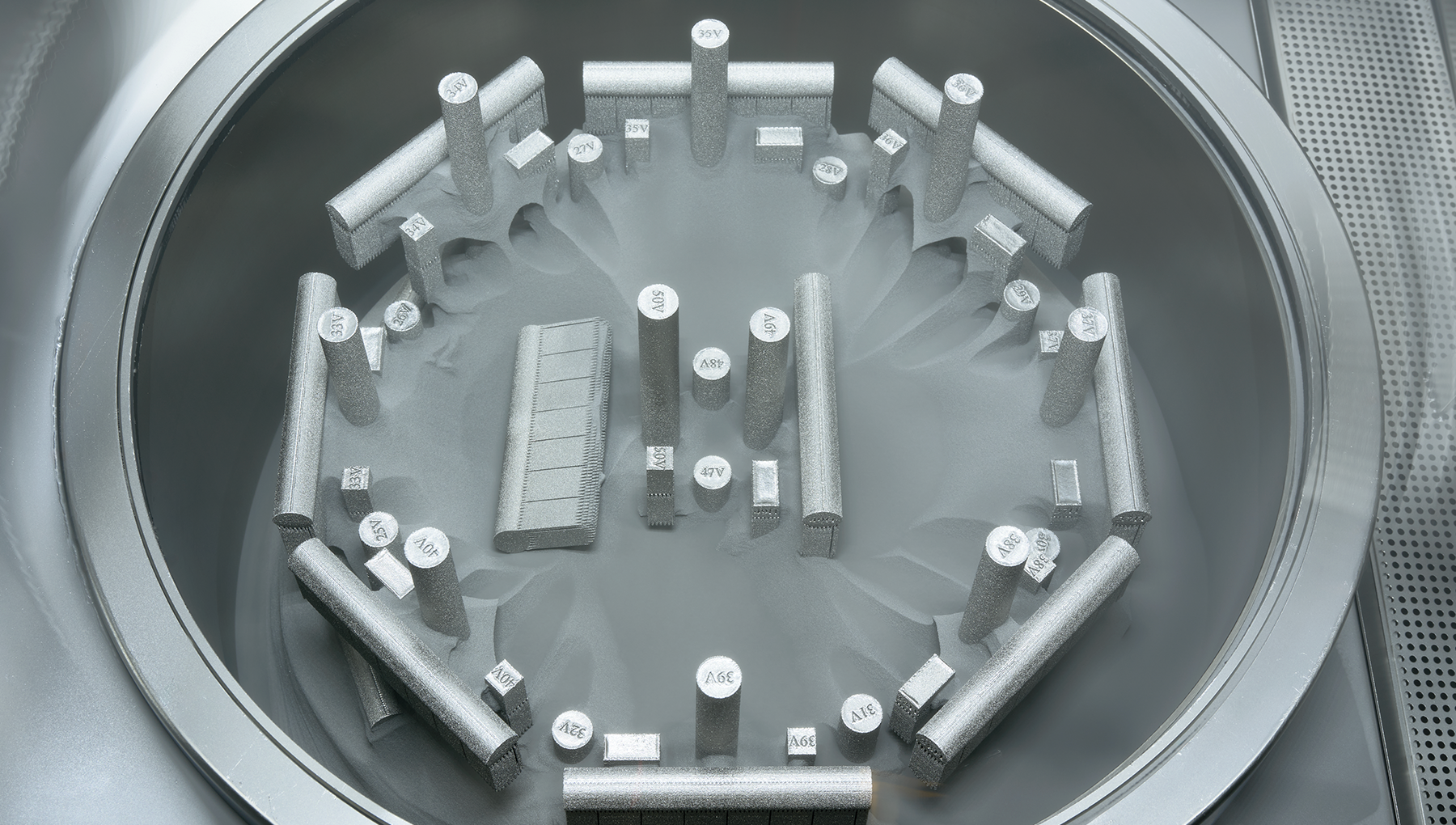

Our latest addition to our Electron Beam Powder Bed Fusion (EB-PBF) product line, the Spectra M, is set to transform the production of medical implants by drastically reducing the additive manufacturing costs while providing unprecedented material properties.

Equipped with EBMControl 6.4, the Spectra M is fully compatible with our innovative Point Melt, Plate Free and Powder Supports technology, ensuring you stay ahead in the rapidly evolving orthopedic industry.

Equipped with EBMControl 6.4, the Spectra M is fully compatible with our innovative Point Melt, Plate Free and Powder Supports technology, ensuring you stay ahead in the rapidly evolving orthopedic industry.

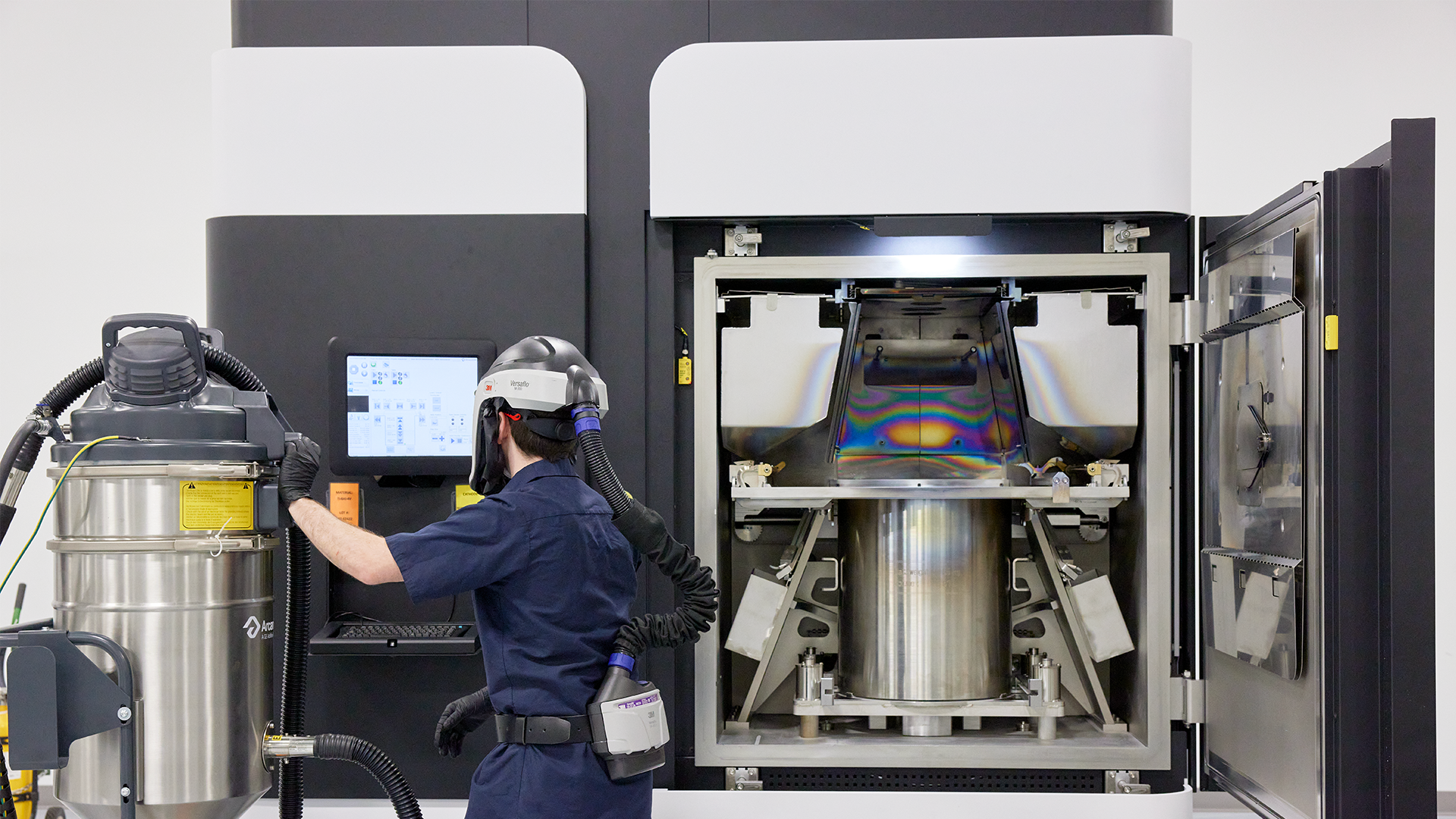

Point Melt technology

EBM Point Melt is a process in which metal powder is melted point by point instead of the usual lines. This technology allows for more accurate temperature control and reduces temperature gradients during the printing of a part. As a result, metal parts made with point melt can benefit from improved surface quality and simpler support structures. Point melt also allows for additional scanning strategies, such as multiple exposures of the same area, which allow better control of the resulting microstructure, especially in the z-direction.